Quantronix Debuts the Revolutionary CubiScan® 225

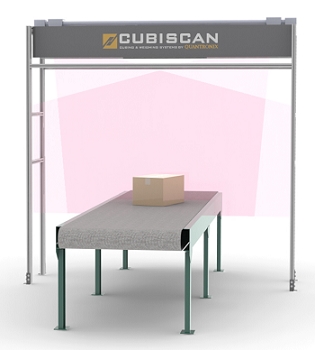

CubiScan 210-DS

The CubiScan® 210-DS is a new generation above-the-belt in-motion dimensioning system for measuring irregular shaped items. It can quickly be installed above existing flat (powered) conveyor belt, thus eliminating the need to breach a conveyor to drop in a cubing system. The 210-DS uses modular components allowing service to be simple, quick and inexpensive. It it capable of measuring on wider conveyors, at higher-speeds, and with more accuracy for more demanding dimensioning applications. It is also type-approved for legal-for-trade applications in the U.S., Canada and the European Union. Several versions (including custom configurations) are available for economical, high-precision and non-cuboidal applications.

Features

The CubiScan 210-DS is high-speed, high-accuracy in-line dimensioning systems. It is a dual sensor system for dimensioning non-cuboidal or cuboidal items in a more demanding cubing application. It is capable of accurately measuring “box”, or “real” volume and is well suited for high-speed distribution and sortation applications.

The CubiScan 210-DS sensors use Class 2 laser technology to measure object length, width and height. The sensors have self-contained controllers for measurement operation and communication output. The system is capable of interfacing to optional scale, bar code scanning and label printing devices, and can communicate with mainframe or PC hosts using Quantronix powerful yet flexible Qbit user and data interface software.

No conveying equipment, or in-line scale?

In cases where a facility has no conveying equipment, or if you’re starting from the ground up, Quantronix can install conveyor with a 210-DS system. As well, weighing functionality can be added with a separate but integrated in-motion conveyor or static (dead-roller) scale. Barcode scanning equipment can also be included, giving you a complete turnkey cubing, DIM weight measuring, and identification/tracking station.

Technical Specifications

- Weight

- Approximately 5 lbs (2.3 kg) per sensor

- Detectable Object Shape

- Almost any

- Useful Field of View

- Maximum 70 degrees

- Measurement Increment Non-LFT and LFT Versions

- 0.2 in (5 mm)

- Object Interval Non-LFT and LFT Versions

- Greater than or equal to 2 in (50 mm)

- Minimum Conveyor Speed Non-LFT and LFT Versions

- 10 fpm (0.05 mps)

- Maximum Conveyor Speed Non-LFT and LFT Versions

- 600 fpm (3.05 mps)

- Object Remission Non-LFT Version

- 15 200%

- Object Remission LFT Version

- 25 200%

- Minimum Object Size Non-LFT and LFT Versions (L x W x H)

- 2.4 x 2.4 x 2.4 in (61 x 61 x 61 mm)

- Maximum Object Size Non-LFT and LFT Versions (L x W x H)

- 60 x 48 x 36 in (1524 x 1220 x 914 mm)

- Sensor Type Non-LFT Version

- SICK

- Object Type LFT Version

- SICK

- Optical Indicators

- 6 LEDs per sensor

- Host Interfaces

- RS-232 or RS-422, Ethernet, Profibus, and Devicenet, Output format is uer-definable

- Laser Diode (Wavelength)

- Visable light (650 nm)

- Laser Power

- Max. 10 mW

- Laser Class of the Device

- Class 2 (Complies w/ 21 CFR 1040.10 w/ exception of the deviations per Laser Notice #50, 07/26/2001

- Enclosure Rating/Protection Class

- IP 20 (according to DIN 40050); with plug cover IP 65

- Housing

- Aluminum die-cast

- Output Data Non-LFT Version

- Max dimensions (L, W, H); Box volume; Real volume

- Output Data LFT Version

- Max dimensions (L, W, H); Box volume

- EMS Test

- In Compliance with EN 61000-6-2:2001, EN 61000-6-4:2001

- Operating Voltage/Power Consumption

- 24 V DC +- 15%/max. 50W

- Vibration Shock Test

- In compliance with EN 60068-2-6, -27, -29, -64

- Temperature (Operation/Storage)

- 23 to 104 degrees fahrenheit / -4 to 158 degrees fahrenheit (-5 to 40 C / -20 to 70 C)